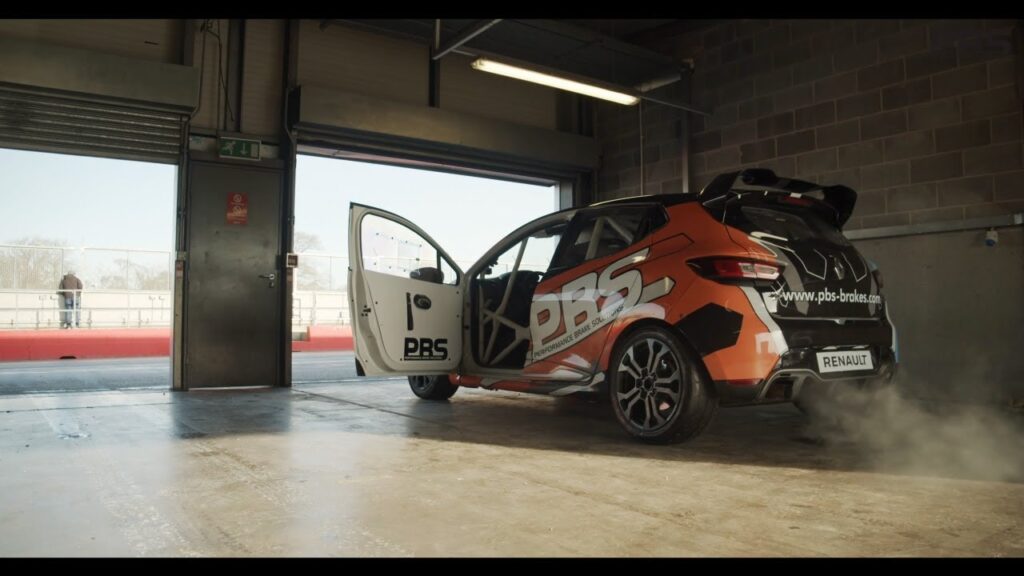

PERFORMANCE BRAKE SOLUTIONS

At Performance Brake Solutions (PBS), we are at the forefront of manufacturing brake pads for competition and track days. We currently support various MSA championships in England, combining our passion for motorsport with our professionalism in manufacturing. We also work directly with several professional racing drivers.PBS has been thoroughly tested in various racing disciplines and competitive events across Europe, demonstrating its outstanding qualities and always striving to deliver the best possible braking performance.

CALIDAD

Brake pads are subjected to enormous pressure from the brake caliper pistons, distributed unevenly across the pad surface. The backing plate must remain perfectly flat to ensure optimal performance. For this reason, the Pro Race compound uses **Nucap NRS backing plates with mechanical hooks**, allowing the compound to bond mechanically to the plate. This provides the best possible retention of the friction material and prevents it from detaching under extreme operating conditions.When brake pads operate at high temperatures, they can generate gases that form a layer between the pad and the disc. This gives the driver the sensation of **reduced braking power**, as the pedal feel remains the same but the car does not decelerate as it should. This effect is known as **“brake fade” or “fading”**, a term commonly used in English even though it literally means *“brake fading”* or *“loss of braking efficiency.”* At PBS, we design a **groove directly into the pad** to provide an escape route for these gases and effectively prevent this phenomenon.

Clients Testimonials

“Getting the coveted high-five in the hallway from an influence is impressive in its own right, but what’s really impressive—and where you ought to focus your outreach efforts—is getting press from influencers in your market.”

“Getting the coveted high-five in the hallway from an influence is impressive in its own right, but what’s really impressive—and where you ought to focus your outreach efforts—is getting press from influencers in your market.”

“Getting the coveted high-five in the hallway from an influence is impressive in its own right, but what’s really impressive—and where you ought to focus your outreach efforts—is getting press from influencers in your market.”

RODAJE

The PBS brake pads undergo a **heat-curing process** during manufacturing. This process removes residual gases that accumulate within the friction material during production, thereby reducing the amount of gas the pad must release during use. Thanks to this treatment, PBS pads require only a **simple bedding-in procedure** to properly mate with the disc.To perform the correct bedding-in, the brake pads should be heated gradually and progressively until they reach approximately **500ºC**, and then allowed to cool down properly. In a circuit environment, this translates to around **14 long and gentle brakings** (roughly two easy laps), followed by a cool-down period in the pits of at least **20–30 minutes**. This bedding process helps eliminate any remaining gas trapped in the pad. Failing to perform proper bedding can lead to product deterioration and reduced performance. In performance analyses, PBS pads have been compared to high-end brands such as **Carbon Lorraine, Carbotech, and Performance Friction**, with the advantage that **PBS offers comparable performance at a significantly lower cost**.

Without a doubt, PBS brake pads are among the most highly regarded on the market, offering excellent consistency, durability, and performance at both low and high temperatures.

Our Perfect Team

George Michael Lee

General Director

“The fool doth think he is wise, but the wise man knows himself to be a fool.”

Jane Doe

Art Director

“A woman is like a tea bag; you never know how strong it is until it’s in hot water.”

Staneley Deo

Marketing

“It is better to be hated for what you are than to be loved for what you are not.”

Jeniffer Baker

Designer

“Good friends, good books, and a sleepy conscience: this is the ideal life.”

When I select my car model, several brake pad options appear. Which one is the correct one?

In some car models—especially those from the VAG group—the same vehicle may come with different possible calipers/pads. There is no fixed pattern: in some cases, it’s random, while in others, it depends on optional systems chosen when purchasing the car.

To avoid mistakes, we recommend removing one of your current brake pads and comparing it with the diagram or shape of the pads listed for your vehicle.

If you’re unsure or your specific pad doesn’t appear, please send us a photo of the pad you need to info@pbsfrenos.es, and we’ll be happy to assist you.

I can’t find my car in the vehicle list.

Although we are constantly developing new references, we don’t yet have brake pads available for every car on the market. If you can’t find your vehicle, please contact us so we can review it on our end and take note of the interest in that particular pad. If a specific pad receives high demand, we will prioritize its release to the market.

I’ve already placed my order, what happens next?

Procuramos disponer de todo el catálogo en stock en el almacén de España, por lo que si el pedido se ha hecho antes de las 16.30h de lunes a jueves, o antes de las 12 los viernes, saldrá a envío el mismo día. Nosotros enviamos la mercancía por servicio 24h, aunque en algunas ocasiones, salvo casos excepcionales, tardan 48h en ser entregadas.

Do I need to use braided (stainless steel) brake lines?

Las pastillas de freno PBS son capaces de trabajar a altas temperaturas, por encima de lo que son capaces de aguantar los latiguillos de freno de goma originales. Si se le va a dar un uso deportivo al coche, sí, recomendamos encarecidamente la instalación de latiguillos de freno metálicos.

Which brake fluid should I use?

For street or spirited driving, PBS600 is more than sufficient. For motorsport use — such as track, rally, or any situation that demands maximum braking performance — we recommend PBS660. Neither of these fluids contains silicone in their composition, so they will not damage your car’s braking system.

I chose the wrong brake pads, can I exchange them?

As long as the pads are returned in perfect condition, in their original packaging and undamaged during transport, yes — you can return them to us. We will then issue you a voucher for the value of the pads, which you can use toward the purchase of the correct ones.

Please note that shipping costs are the responsibility of the customer.

Are they noisy?

When it comes to brake squeal, the disc alloy plays a major role. ProTrack pads are generally quiet, except when used with DBA discs. Pro Race pads tend to be noisy, although we’ve encountered cases where they don’t squeal. The same applies to the ProComp compound, which is usually quite loud, but for example, when paired with EBC Racing two-piece discs, they produce very little noise.

A proper bedding-in process helps reduce noise.

During hard braking, the noise created by the pad’s bite on the disc, a kind of humming sound, is completely normal for any performance pad, especially when using slotted or drilled discs.

Do they produce a lot of dust?

Like all performance brake pads, yes, they do produce dust. If we want the pads to deliver strong performance, this is unavoidable.